Services

SERVICES

SOLUTIONS

TECHNOLOGIES

Industries

Insights

TRENDING TOPICS

INDUSTRY-RELATED TOPICS

OUR EXPERTS

February 28, 2025

According to the recent history of Internet of things, growing market competition and rising product quality expectations influence manufacturers to adopt IIoT technology and better control production processes and equipment maintenance, automate industrial data collection, and enable informed decision-making.

| In 2024, the global industrial IoT market was valued at $194.4 billion and is estimated to reach an outstanding $286.3 billion by 2029, growing at an 8.1% annual rate | |

|---|---|

| The manufacturing sector holds the second-largest share in the IoT market, surpassed only by the healthcare industry | |

| The number of industrial IoT devices is expected to reach 152 million by 2025 | |

| The global wireless industrial IoT sensor market is expected to reach $16.1 billion by 2032, growing at a CAGR of 12.3% compared to 2023 |

Scheme title: Industrial IoT Market: Global Forecast to 2029, USD BN

Data source: Markets and Markets 2024

*Forecast

Concentrated

Fragmented

Market concentration

Low

High

Market Growth Stage

Decelerating

Accelerating

Pace of Market Growth

Low

High

Degree of innovation

Level of M&A activities

Impact of regulations

Product substitutes

End-user concentration

Scheme title: The US industrial Internet of Things market concentration & characteristics

Data source: Grand View Research, 2023

| The US industrial IoT market is expected to grow at a CAGR of over 18% from 2024 to 2030 | |

|---|---|

| The industrial IoT market in Europe is expected to witness a CAGR of over 22% from 2024 to 2030 | |

| The industrial IoT market in the UK accounted for a revenue share of about 22% in Europe in 2023 | |

| The Asia Pacific industrial Internet of Things market is expected to grow at a CAGR of over 26% from 2024 to 2030 | |

| The industrial Internet of Things market in India is expected to grow at the fastest CAGR of over 29% from 2024 to 2030 | |

| In 2025, the number of IIoT devices per industrial establishment in North America is expected to reach 365 | |

| By 2025, the Asia Pacific region is expected to dominate IIoT data generation, capturing a remarkable 58% of the global total—a significant rise from 46% in 2020 | |

| Europe is expected to account for a 23% share of IIoT generated data across the globe in 2025, exhibiting a drop from a 28% share in 2020 | |

| The share of IIoT generated data in North America is estimated to drop from 21% in 2020 to 16% in 2025 |

Scheme title: Smart sensor market share by region

Data source: Data Insights Market

IoT technology connects industrial equipment and facilitates machine-to-machine communication, as well as industrial data collection and data processing. Here, we have gathered the top use cases of IoT in manufacturing.

With IoT sensors installed in industrial machinery, companies can monitor its performance in real time and spot any inconsistency or drop in the machinery output, allowing technicians to perform timely diagnostics and fix issues before they lead to serious breakdowns.

| About 28% of EU manufacturing companies use IoT to track the maintenance needs of industrial machines | |

|---|---|

| In 2023, over 50% of manufacturing companies considered predictive maintenance as a strategic priority | |

| IoT infrastructure is considered the key component of predictive maintenance systems, together with big data, advanced analytics, cloud computing, as well as distributed control systems and programmable logic controllers | |

| In a recent study by Siemens, the researched companies reduced unplanned downtime from 39 hours per month in 2019 to 27 hours per month in 2024 thanks to the introduction of IoT-enabled predictive maintenance | |

| The adoption of asset condition monitoring and predictive maintenance practices can save companies $388 billion due to a 5% increase in overall productivity |

Scheme title: Cost of one-hour unplanned plant downtime, Heavy, Automotive, FMCG, and Oil & Gas sectors

combined

Data source: Siemens 2024

Industrial companies apply IoT technology to track and monitor their equipment, fleet, and inventory using RFID tags and smart devices.

| The global IoT-based asset tracking and monitoring market is predicted to grow at a 12.5% annual growth rate and reach $10 billion in value by 2032 | |

|---|---|

| The Asia-Pacific IoT-based asset tracking and monitoring market is predicted to reach $4.11 billion by 2033, growing at a CAGR of 8.7% compared to 2023 | |

| The Europe IoT-based asset tracking and monitoring market is expected to grow from 2024 to 2033 with a CAGR of 10.1% | |

| The manufacturing segment holds the second-largest share of the IoT-based asset tracking and monitoring market, dominated only by the logistics and transportation domain | |

| The manufacturing segment of the IoT-based asset tracking and monitoring application market is expected to reach 2.9 billion by 2033 | |

| About 18% of manufacturing companies in the EU incorporate IoT sensors for warehouse management |

Scheme title: IoT-based asset tracking and monitoring market share, by region, 2023

Data source: Precedence Research

Strategic development index

Scheme title: IoT-based Asset Tracking and Monitoring Market Competition Analysis

Data source: Research and markets 2022

The implementation of IIoT solutions into the supply chain allows companies to optimize processes by automatically collecting information and providing real-time insights into inventory location, condition, storage, and delivery, improving efficiency and reducing costs.

| The global IoT supply chain market is expected to reach $41.8 billion in 2033, growing at a CAGR of 12.9% from 2023 | |

|---|---|

| In 2024, 54% of companies used IoT technology to track their supply chain processes | |

| Being a global manufacturing hub, China will create a strong demand for IoT solutions in the supply chain, with its IoT supply chain market share expected to reach $10.4 billion by 2033 | |

| About 80% of manufacturing CEOs have reported that their businesses have been heavily affected by supply chain disruptions over the last 12 to 18 months | |

| Only 16% of manufacturing executives confirm they have real-time monitoring across their entire supply chain | |

| In 2024, 70% of mining companies highlighted improved customer experience and the significant impact of IoT implementation on the supply chain |

Scheme title: Percentage of companies with implemented real-time supply chain monitoring distributed by

regions

Data source: Zebra Manufacturing Vision Study 2024

IoT solutions with smart sensors, edge devices, and advanced analytics components can save companies millions of dollars by monitoring energy levels in real time, adjusting power usage, as well as analyzing consumption trends and identifying optimization opportunities.

| In the first quarter of 2024, about 55% of companies reported applying IoT technology for energy monitoring | |

|---|---|

| About 35% of all EU manufacturing companies use IoT for energy consumption management | |

| IoT-enabled smart thermostats in HVAC systems can help achieve up to 10% energy savings | |

| IoT-powered advanced lighting controls can help save up to 45% of consumed energy | |

| Smart air quality sensors, occupancy sensors, and real-time ventilation controllers can help save up to 40% of energy consumed in a facility like a laboratory |

Scheme title: Global IoT energy management market share, by application

Data source: Fortune Business Insights, 2022

According to the National Safety Council, approximately 839 people die per year from exposure to harmful substances and about 740 as a result of unfortunate contact with objects or equipment in the USA. In 2022, the total cost of such work injuries was estimated at $167 billion, which amounts to approximately $1,040 per worker. Implementing IoT technology helps detect dangerous conditions on shop floors, saving the lives of employees and preventing them from various injuries.

| The global industrial safety market, which incorporates IoT technology, smart sensors, and wearables, was estimated at $6.2 billion in 2024 and is expected to reach $8.9 billion by 2030, growing at a CAGR of 6.3% | |

|---|---|

| The oil & gas segment of the global industrial safety market accounted for the largest market share over the forecast period from 2023 to 2032 | |

| The potential economic value of IoT for health and safety usage in the oil & gas setting is estimated to reach from $7 to $20 billion by 2030 | |

| In 2023, the safety sensor segment of the global industrial safety market held the largest market share of 25% |

Largest category

Expected to witness high growth rate

Scheme title: The global industrial safety market, by product

Data source: P&S Intelligence

Introducing industrial IoT technology for quality control activities helps increase production automation, minimize the number of products with defects, and increase customer satisfaction with end-products.

| About 55% of companies use IoT for quality control and management in 2024 | |

|---|---|

| About 32% of manufacturing companies in the EU employ IoT devices to manage and automate production processes | |

| An Audi manufacturing facility inspects 100% of the produced vehicles per day thanks to the IoT solution delivered by Intel |

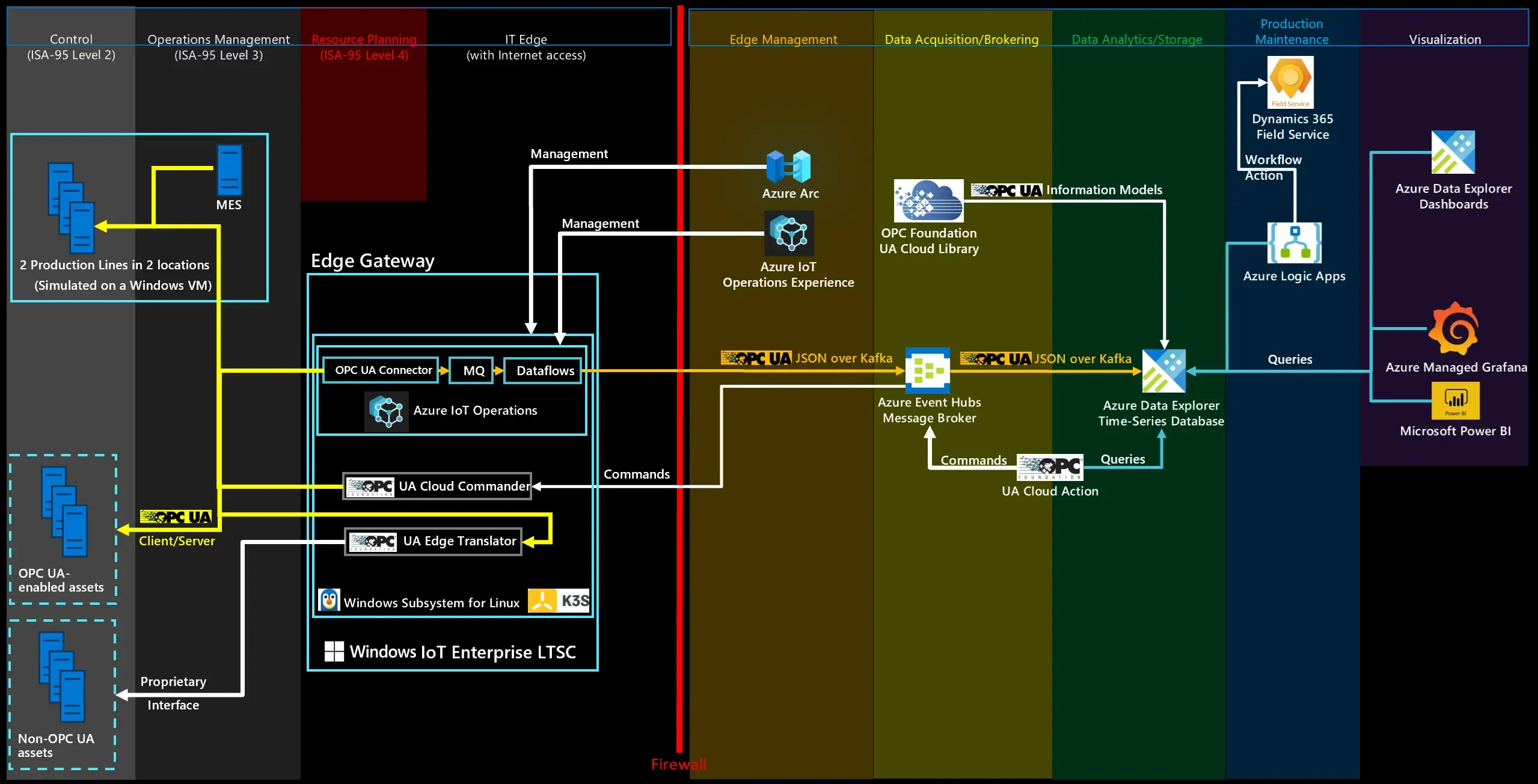

Industrial IoT architectures can vary depending on manufacturing organizations’ production processes and existing levels of industrial automation. Below, we provide a sample IIoT architecture based on the Microsoft software ecosystem.

Scheme title: An example of Industrial IoT architecture based on the Microsoft ecosystem

Data source: Microsoft 2024

Scheme title: Data transfer protocols used in IIoT

Data source: HiveMQ 2024

McKinsey emphasizes that no single application will drive outsize growth, but instead the broad execution of technologies is key. This aligns directly with the Industry 4.0 approach, which requires manufacturing companies to complement industrial IoT with other technologies, like edge and cloud computing, artificial intelligence and machine learning, big data, and robotics.

Scheme title: Focus on current investments in manufacturing technologies

Data source: Deloitte 2023

Scheme title: Core Industry 4.0 technologies and sample use cases

Data source: McKinsey

Scheme title: Industry 4.0 market size 2023 to 2024, USD billion

Data source: Precedence Research

Scheme title: Industry 4.0 market share, by region, 2023

Data source: Precedence Research

| The manufacturing segment dominates the global Industry 4.0 market with a revenue share of approximately 31% | |

|---|---|

| In 2022, the industrial Internet of Things held a significant Industry 4.0 market share of 27% | |

| Edge computing is already integrated by 40% of industrial goods & equipment companies |

Scheme title: How edge delivers value in the IoT ecosystem

Data source: Capgemini

| The global 5G industrial IoT market is estimated to hit $9.41 billion by 2031, growing at a CAGR of 28% | |

|---|---|

| 5G IoT hardware unit sales for Industry 4.0 applications are estimated to reach 22.3 million units by 2030 | |

| The market of AI in manufacturing is predicted to reach $20.8 billion by 2028, growing with a CAGR of 45.6% from 202 | |

| Almost half of the respondents are already integrating machine learning and AI technology into their IIoT strategy |

The industrial IoT markets across the globe experience significant growth due to the multiple advantages that IIoT technology brings to the shop floors. Here are the major benefits that industrial companies gain from using IoT and several real-life examples that highlight industrial IoT's value in action.

Scheme title: Benefits that companies plan to gain from IIoT implementation Data source: HiveMQ 2024

| In 2024, about 73% of companies in the energy sector reported better decision-making, improved health and safety, and reduced downtime thanks to IoT implementation | |

|---|---|

| Almost 90% of manufacturing industry CEOs believe that the convergence of IT and OT into industrial IoT helps companies save money and resources |

| The adoption of IIoT-enabled production visibility helped increase equipment utilization from 20% to 60% and equipment effectiveness from 57% to 85%, as well as boosted the number of quality end-product parts from around 4,200 to over 10,000 for Paragon Medical, a healthcare device manufacturer | |

|---|---|

| By integrating intelligent sensors and actuators into each piece of equipment and connecting every machine to the central IoT platform, Airbus has implemented a smart factory that helped establish better control of its production workflows, streamline its industrial processes, and ensure error-proof shop-floor operations | |

| Avalign Technologies implemented an industrial IoT solution and managed to improve their overall equipment effectiveness from 30% to 80%, reduce machine idle time from 980 hours to 2 hours, and generate over $4.5 million thanks to increased production throughput | |

| After introducing wearable technology for its employees and equipping industrial facilities with environmental sensors, North Star BlueScope Steel was able to track real-time data on workers' body temperature, heart rate, and activity levels, as well as temperature and humidity on the shop floor, to identify potential risks to workers’ health and provide personalized safety guidelines | |

| The IoT-enabled digital twin technology helps Unilever gain visibility across its production processes and provides shop-floor operators with control over production consistency. Also, by analyzing the collected historical data with machine learning and advanced analytics techniques, the company gets useful insights or predicts possible outcomes | |

| Implementing IIoT at the Microsoft plant in China helped the company identify products on the verge of obsolescence, allowing it to save almost $5 million in one year and cut inventory costs by $200 million | |

| Procter & Gamble’s Rakona plant in the Czech Republic implemented IoT smart devices for the quality-control system and managed to reduce reworking and complaints by 50% and throughput time by 24 hours thanks to the timely identification of quality deviations |

Despite the numerous benefits IIoT systems can bring, their implementation is fraught with potential business risks, such as insufficient leadership support, budget constraints, uncertain ROI, and lack of reliable IoT security solutions to protect industrial IoT applications.

Scheme title: Barriers organizations face when deploying IoT projects

Data source: Viasat Enterprise

| About 58% of IoT project failures are attributed to problems at the device level | |

|---|---|

| Security is a top challenge for manufacturing companies adopting IoT | |

| 31% of companies consider lack of budgeting and ROI uncertainty as their top IIoT implementation challenge | |

| 35% of companies mentioned cybersecurity as their major concern for new IIoT adoption | |

| Nearly one-third (33%) of surveyed organizations reported experiencing six or more cyber intrusions in their IT/OT environment in 2024, compared to 11% of respondents the year before | |

| About 48% of the surveyed companies admitted that cyber criminals compromised their weak IoT/network devices |

Scheme title: Techniques involved in cybersecurity incidents

Data source: Fortinet, 2024

*Before 2024, these answers were part of “What types of intrusions were experienced?”

Scheme title: Riskiest IoT devices in a manufacturing environment

Data source: Forescout Research Labs

We offer professional support with industrial IoT technology adoption and utilization, including:

We provide end-to-end industrial IoT development and implementation services that cover:

The fourth industrial revolution has brought many technological advancements to the industrial floor, and the

Internet of Things is one of the most commonly implemented technologies. Despite the existing technology

challenges and cybersecurity concerns, industrial companies should nevertheless consider implementing the

technology to capitalize on the multiple benefits IoT can bring. Numerous successful examples of international

companies prove that industrial IoT helps increase productivity through process automation, improve equipment

performance and its longevity, and minimize production downtime.

Leveraging 25+ years in IT consulting and

software development services, Itransition can help you develop a risk-free IIoT adoption roadmap, as well as design

and implement secure and reliable IoT solutions, addressing possible budget, security, and adoption concerns.

Service

Itransition helps industrial companies implement secure IoT systems for production control, predictive asset maintenance, and effective supply chain management.

Insights

How to achieve unfailing IIoT security? Explore the most common threats and develop a feasible strategy to effectively overcome them.

Insights

Discover how IoT can help manufacturers optimize supply chains, energy management, enhance inventory management, improve product performance, and boost revenue.

Insights

Learn about the architecture, main benefits, use cases, and prominent real-life examples of IoT data analytics and explore a detailed implementation guide.

Service

Itransition delivers scalable software to help manufacturers automate business processes, optimize manufacturing operations, and improve decision-making.

Service

Discover Itransition’s services to help companies adopt custom manufacturing software, along with key solutions, technologies, and guidelines.